For anyone immersed in the world of guitar creation or repair, Stewart-MacDonald, or StewMac as it’s commonly known, is a name synonymous with quality and expertise. As a content creator for guitarplayers.net, I understand the reliance many luthiers and builders place on StewMac for specialized tools and Stewart Mac Guitar Parts. StewMac stands as a premier global source for guitar making essentials, offering everything from tools to parts and supplies. Recently, I had the opportunity to evaluate their new Laser-Cut Wood Guitar Binding sets, and I’m excited to share my insights in this review.

Unboxing the Laser-Cut Wood Guitar Binding Sets from StewMac

StewMac’s Laser-Cut Binding Sets are available in three wood types to cater to diverse aesthetic preferences: Flamed Maple, Plain Maple, and Rosewood. Each set is thoughtfully assembled, including body binding, fingerboard binding, a back strip, end trim, heel cap, and even a truss rod cover – all meticulously crafted from a single piece of wood. For this review, I focused on the flamed maple set. My initial impression was immediately positive, largely because I vividly recall the challenges of my early guitar building days. Lacking proper tools and equipment, preparing flamed maple for sides or binding was a significant hurdle. I resorted to time-consuming and sometimes risky methods. These laser-cut binding sets promise to be a significant boon, saving both time and potentially money for builders who lack the resources to create bindings from scratch. But the benefits extend beyond mere convenience. Let’s delve deeper into my experience with this product.

Achieving Perfect Color Harmony

Close-up of the Laser-cut Flamed Maple Wood Binding Set showcasing color consistency

Close-up of the Laser-cut Flamed Maple Wood Binding Set showcasing color consistency

One aspect I prioritize is ensuring a seamless color and figure match across all bindings. In my archtop builds, I often repurpose offcuts from guitar sides for binding, aiming for color consistency since all body bindings originate from the same piece. However, material availability can be a constraint, especially after cutting the guitar sides. While side material usually suffices for body bindings, other components are often left wanting.

StewMac’s laser-cut binding sets effectively solve this issue, offering a comprehensive solution that guarantees a perfect match not just for body bindings but also for fingerboard binding, truss rod cover, backstrip, and end graft. This level of color and grain consistency elevates the overall aesthetic and professional finish of the instrument, a testament to the thoughtful design of these stewart mac guitar parts.

Consistent Thickness and Superior Surface Finish

Close-up showing the smooth surface and uniform thickness of StewMac laser-cut binding

Close-up showing the smooth surface and uniform thickness of StewMac laser-cut binding

Surface preparation is critical before bending binding material. Examining the laser-cut binding sheet, I noted the excellent sanding quality and finish. The surface is smooth and ready for bending, whether using a side bender or a hot bending iron. Furthermore, the thickness measures precisely 0.085 inches, which aligns perfectly with my preferred thickness before bending. This precise thickness is a significant time-saver, eliminating a crucial step in the binding preparation process. This attention to detail in stewart mac guitar parts preparation is truly commendable.

Effortless Part Removal

StewMac laser-cut binding sheet with parts partially removed using a scalpel

StewMac laser-cut binding sheet with parts partially removed using a scalpel

Removing the individual binding parts from the sheet is designed to be both safe and straightforward. Initially, I used a scalpel to score the connecting tabs, then gently rotated the part to detach it. This method worked well, allowing for precise separation without damaging the delicate wood.

Close-up of a binding part being detached from the sheet

Close-up of a binding part being detached from the sheet

However, I discovered an even more efficient technique. Switching to a chisel to slightly cut the tabs from each side of the piece proved to be quicker and easier.

Binding parts fully removed from the laser-cut sheet, showcasing clean edges

Binding parts fully removed from the laser-cut sheet, showcasing clean edges

Both methods ensure clean removal, maintaining the integrity of each stewart mac guitar part. The ease of removal is a testament to the precision of the laser-cutting process.

Prepping Laser-Cut Edges for Bending

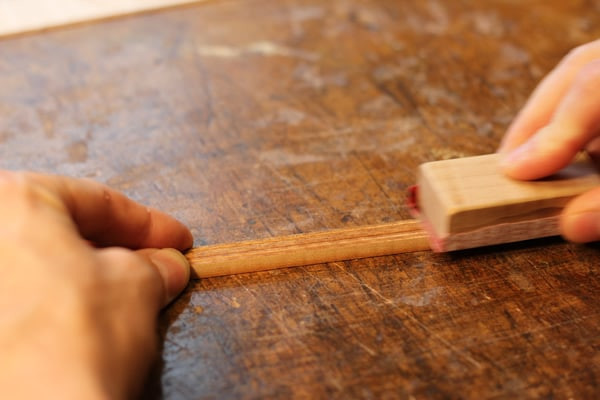

Sanding block being used to smooth the edges of a laser-cut binding strip

Sanding block being used to smooth the edges of a laser-cut binding strip

After detaching the binding pieces, minimal prep work is needed on the laser-cut edges. Minor bumps may remain where the tabs connected the parts, and the lasered surface might feel slightly rough to the touch. A quick touch-up with a sanding block and 150 grit sandpaper smooths out these minor imperfections. Within minutes, the edges are refined, smooth, and perfectly prepared for the bending process. This minimal cleanup needed for stewart mac guitar parts further enhances efficiency.

Adaptability for Custom Guitar Designs

StewMac laser-cut binding sheet laid out against a non-traditional guitar body shape

StewMac laser-cut binding sheet laid out against a non-traditional guitar body shape

While designed for traditional guitar shapes, the versatility of these laser-cut binding sets is worth exploring for non-traditional designs. My own guitar designs often deviate from standard templates, prompting me to assess if these sets could still provide all necessary parts.

Close-up showing the truss rod cover part and extra wood available in the StewMac binding sheet

Close-up showing the truss rod cover part and extra wood available in the StewMac binding sheet

The primary consideration for my custom builds was the truss rod cover. My design features more material above the screw hole, which initially seemed incompatible with the pre-cut part. However, the sheet provides ample extra wood from which a custom truss rod cover can be fashioned. Even after cutting a custom truss rod cover, sufficient material remains for contingencies. Having this extra material within the stewart mac guitar parts set is a valuable safety net.

The Benefit of Extra Binding Strips

Five binding strips included in the StewMac laser-cut binding set

Five binding strips included in the StewMac laser-cut binding set

Speaking of contingencies, I habitually prepare five pieces of body binding, even bending the fifth piece alongside the others. This practice is born from the unique nature of my guitar builds. Should a binding piece break, especially during intricate steps like bending around a cutaway, having a spare eliminates the need to restart the binding creation process from scratch – a process that can span days due to glue drying times and various steps like band-sawing and thicknessing. The inclusion of five binding strips in the laser-cut set is a welcome feature, perfectly aligning with my workflow and offering essential backup stewart mac guitar parts.

Addressing Fingerboard Binding Needs

Fingerboard binding pieces within the StewMac laser-cut binding set

Fingerboard binding pieces within the StewMac laser-cut binding set

Even if one binding strip is used as a backup for the body, the set still provides sufficient material for fingerboard binding sides. Crucially, there’s also enough material to create the binding that wraps around the fingerboard end. This thoughtful inclusion ensures comprehensive binding coverage for the entire instrument, making these stewart mac guitar parts truly comprehensive.

Final Verdict

For those starting their journey in guitar building, or seasoned luthiers seeking to enhance efficiency without compromising quality, StewMac’s laser-cut guitar binding sets are an invaluable asset. These sets would have been an immense advantage during my early building days, when access to specialized machinery and tools was limited. The precision, consistency, and time-saving benefits offered by these stewart mac guitar parts make them a highly recommended addition to any luthier’s toolkit.

Explore StewMac’s Laser-Cut Wood Bindings and discover how they can streamline your guitar building process.