When delving into the specifications of a guitar, the term “nut” frequently surfaces. While it might seem like a minor component, the nut is indispensable; a guitar simply cannot function without it. This small piece, typically crafted from materials like bone, plastic, or graphite, plays a crucial role in aligning the strings as they journey towards the headstock. Often overlooked and far from glamorous, the guitar nut is, in reality, fundamental to a guitar’s playability, tuning stability, and even its tone. Given its significant impact on the performance of any stringed instrument, tasks like replacing or repairing a nut are best entrusted to experienced professionals. Why? Because a poorly executed nut job can negatively affect virtually every aspect of a guitar’s performance. From frustrating buzzing and uneven action to compromised intonation and unreliable pitch return after string bends or tremolo use – when the nut isn’t right, a guitarist will undoubtedly notice.

While the nut is undeniably critical for a guitar that plays and sounds great, its primary function is quite straightforward. It’s essentially a guide and spacer for the strings. However, as any guitar enthusiast knows, even the simplest guitar components can be surprisingly complex when you dive into the details. So, let’s explore the ins and outs of the guitar nut.

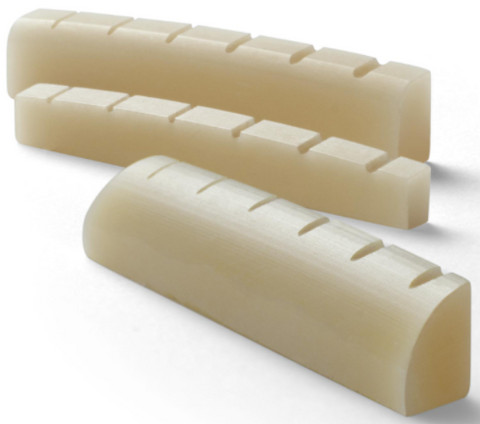

Just a few nuts for guitar

Just a few nuts for guitar

Variety of guitar nuts made from different materials.

It’s crucial to clarify one key point right away: the nut exclusively influences the sound of open, unfretted strings. Once a string is fretted at any point on the neck, the nut is effectively removed from the equation and no longer contributes to the tone. Despite this limited tonal impact (affecting only open strings), the nut profoundly affects playability across the entire fretboard. This is precisely why the correct installation, precise slotting, and careful dressing of a guitar nut are paramount – arguably even more so than the specific material from which it’s made.

The nut on a Gibson Les Paul Custom

The nut on a Gibson Les Paul Custom

Close-up of a guitar nut on a Gibson Les Paul Custom headstock.

Understanding Common Guitar Nut Specifications

When manufacturers discuss guitar nuts, they most commonly emphasize two specifications: width and materials. And truthfully, these are indeed the two primary considerations when evaluating a guitar nut. Nut width refers to the span across the fretboard, from the bass string side to the treble string side. Material simply indicates what the nut is manufactured from. Let’s delve deeper into each of these.

Nut Width: Spacing for Your Fingers

Every guitar is defined by its nut width. This measurement, easily taken from the bass side to the treble side of the nut (the small piece before the headstock), is a surprisingly critical factor in a player’s experience. Nut width is often cited as a “make-or-break” specification for many guitarists. If the strings are spaced too widely or too narrowly for an individual’s fingers, it can lead to constantly misfretting and landing on incorrect strings. Electric guitarists who have attempted to transition to a 2-inch nut width nylon-string classical guitar can certainly attest to this!

This is how we measure nut width

This is how we measure nut width

Demonstration of measuring the nut width of a guitar with calipers.

Notable Guitar Nut Width Examples:

Here’s a glimpse into some common nut widths found on various guitar types:

- Vintage Fender: 1.650” (41.9mm)

- Modern Fender: 1.6875” (42.8625mm)

- Some Vintage and Less Common Fenders: 1.625” (41.28mm)

- Gibson: Ranging from 1.69” to 1.72”

- Late 1960s, Early 1970s Gibsons (narrow necks): 1.5625”

- Martin Acoustics: 1.75” and 1 and 7/8”

- Taylor Acoustics: 1.6875” on more affordable models, 1.75” on 300 Series and higher. 1 and 7/8” on Nylon-string and 12-string guitars.

- Classical Guitars: 2”

This is not an exhaustive compilation, but the majority of guitar manufacturers utilize measurements within this range. For precise specifications, it’s always best to consult the manufacturer’s information for a specific model, as this detail has become increasingly important for guitar sales. Unconventional or overly wide/narrow nut widths are generally avoided, as familiarity and comfort are often preferred in this specification.

Currently, a nut width around 1 and 11/16” (or 1.6875” or 43 mm) has become a widely accepted standard for comfortable playability in both acoustic and electric guitars. Many steel-string acoustic guitars, particularly those favored by fingerstyle players, may feature wider nuts at 1 and 3/4” or 1 7/8” to provide extra string spacing. However, 1 and 7/8” can feel excessively wide for players accustomed to 1 and 11/16”. Even a seemingly small difference of less than a quarter of an inch is readily noticeable to the fretting hand!

Classical and Flamenco guitars typically employ a 2” nut width. This wider spacing accommodates the broader nylon strings and the chord-focused playing style prevalent in these genres. However, some contemporary nylon-string guitars, particularly those from manufacturers like Taylor and Godin, are adopting slightly narrower nut widths (e.g., 1 and 7/8”) to appeal to steel-string players, as the full 2” width can feel cumbersome to those unfamiliar with classical guitars.

The Tusq Nut of a Nylon String Taylor Guitar

The Tusq Nut of a Nylon String Taylor Guitar

A Tusq nut on a Taylor nylon-string guitar, showcasing a narrower 1 7/8″ width.

Bass guitars also warrant consideration, though the situation is more nuanced due to the variety of string configurations. 4-string basses can range from a slim 1.437” (classic Jazz Bass) to 1.75” on many modern models. This quarter-inch difference is definitely perceptible to the fretting hand. Adding more strings naturally increases nut width. For example, a 5-string Jazz Bass might have a nut width of 1.85” or 1.875”. However, some manufacturers, like ESP, attempt to maintain slimmer nut widths on their 5-string basses for broader appeal. The bottom line for bass shopping: pay attention to nut width and ensure it feels comfortable in your hand.

The Bakelite Nut on a Rickenbacker 4003 Bass

The Bakelite Nut on a Rickenbacker 4003 Bass

A Bakelite nut on a Rickenbacker 4003 bass guitar.

While nut width is generally fixed, the nut material is easily changed to align with player preferences. So, don’t dismiss an otherwise exceptional guitar simply because of the factory nut material!

A Diverse Range of Nut Materials and Their Impact on Tone

Throughout guitar history, a wide array of materials have been utilized for nuts. While nut width has no bearing on tone, the material absolutely and undeniably influences the tone of open strings. Early materials included brass, steel, and aluminum. While incredibly durable, these metals are not generally considered tonally optimal (in many opinions). Bone gradually emerged as the preferred material, praised for its balanced tone, good sustain, durability, and workability. Today, bone remains a popular choice, alongside high-tech plastics like Corian, Micarta, and Tusq, which have gained significant traction.

Import guitar manufacturers often simply list “Plastic” as the nut material, leaving it vague. However, the type of plastic can vary considerably. Many players and luthiers often choose to replace generic plastic nuts with organic materials or higher-quality synthetics. The image below shows a basic plastic nut on a Squier guitar. It lacks refined dressing and appears somewhat bulky and sharp compared to nuts found on USA-made or Custom Shop Fender guitars.

The plastic nut on a Squier Classic Vibe Stratocaster

The plastic nut on a Squier Classic Vibe Stratocaster

A stark white plastic nut on a Squier Classic Vibe Stratocaster guitar.

Bone has long been regarded as the gold standard for tone, though this is ultimately subjective. Perhaps its reputation stems from familiarity and tradition? Ultimately, if a material sounds “best” to your ears, then it is the best for you! Your personal playing experience should always take precedence over others’ opinions. Don’t compromise your guitar’s playability or tone based on external viewpoints. Observe the well-shaped, low-profile, and smoothly finished bone nut on the Custom Shop Stratocaster pictured below.

The bone nut on a Fender Custom Shop Stratocaster

The bone nut on a Fender Custom Shop Stratocaster

A meticulously crafted bone nut on a Fender Custom Shop Strat Relic guitar.

While bone is a time-honored choice with a pleasing, “vintage” tone (however you define it), it does have limitations. Inconsistent density is a primary concern. Bone can exhibit variations in density, with harder and softer areas. This can hinder uniform resonance transfer. Any organic material is likely to have some degree of density variation. This doesn’t automatically equate to inferior sound or performance, and you may never encounter tangible evidence of density inconsistencies in your bone nut. Another drawback of bone: cutting or filing it produces a truly unpleasant odor, often likened to burning hair.

Enter alternative materials! Tusq nuts, manufactured by Graph-Tech, are marketed as a more consistent and tonally engineered product. Tusq combines organic components with a manufacturing process designed to ensure uniform density for optimal tone transfer. Taylor Guitars, a leading acoustic guitar brand for the past two decades, has been a prominent user of Tusq nuts, attesting to its reliability and performance. Corian (an engineered stone similar to quartz) and Micarta (layers of fabric bonded with phenolic resin, then heated and compressed for hardness) are other high-tech materials commonly used for nuts. Gibson has utilized both Corian and Micarta in the past, but has transitioned to Graph-Tech/Tusq for their USA production models.

The Tusq Nut on a PRS

The Tusq Nut on a PRS

A Tusq nut from GraphTech on a PRS electric guitar.

Other nut materials encountered include brass (used on some 2014 Gibsons), steel (Floyd Rose and LSR roller nuts, Wilkinson nuts on Jeff Beck Strats), nylon (Custom Shop Les Pauls), ebony (on Martin Reissue models), fossilized ivory, fossilized walrus tusk, and black buffalo horn. These materials exhibit a wide spectrum of hardness and demonstrably affect the tone of open strings. For many players, brass and steel nuts are considered less desirable tonally, with nylon in the middle range, and bone and fossilized ivory often ranked highest. Numerous online resources delve into the tonal nuances of different nut materials – a worthwhile rabbit hole to explore. Just remember the crucial point: the nut only affects the tone of open, unfretted strings!

A steel nut on a Vintage Vox 12 String

A steel nut on a Vintage Vox 12 String

A steel nut on a vintage 1960s Vox 12-string guitar.

Food for Thought on Nut Materials

It’s intriguing to note that the 1959 Les Paul, often hailed as the greatest Les Paul (perhaps even guitar) of all time, was equipped with a nylon nut. Yet, surprisingly few Gibson owners opt to replace their nuts with nylon! Why is this? Perhaps guitarists are simply unaware of nylon’s tonal qualities. In truth, nylon nuts can be more challenging for technicians to work with compared to bone, requiring specialized skills for proper slotting. However, nylon is undeniably a smooth and tonally rich material. When expertly slotted, it becomes another excellent nut choice.

A Nylon Nut on a 59 Les Paul Reissue

A Nylon Nut on a 59 Les Paul Reissue

A nylon nut on a 1959 Les Paul Reissue guitar.

Additional Nut Considerations

New Frets, New Nut?: When your guitar undergoes a refret, replacing the nut should be a serious consideration. A competent luthier will typically adjust (lower) the nut slot height when refretting, as the new frets will be taller than the worn-down originals. Failing to adjust the nut height results in higher action. If your guitar has had multiple fret level and crown jobs over time, the nut slots would ideally have been lowered with each job to match the reduced fret height. When refretting with taller frets, reusing the old nut, with its now deeply cut slots, would necessitate filling and re-slotting. While this is feasible, it introduces multiple materials (e.g., baking soda and super glue) into the nut. Therefore, nut replacement is often recommended during a refret for optimal performance and material integrity.

Nut Dressing for Specific String Gauges: Players who experiment with different string gauges quickly learn that simply “throwing on a set of 13s” and tuning down to C standard isn’t a recipe for success. Nut slots need to be filed to the correct width and angle to accommodate heavier gauge strings and ensure proper performance. Nut slotting files (like those from StewMac) facilitate this process for skilled individuals. However, even the best tools in inexperienced hands can lead to problems.

Consider a Fender Player Stratocaster, factory-slotted for 9-42 gauge strings. If you switch to 11-gauge strings, the thicker strings will likely sit on top of the nut slots rather than within them. This can cause tuning instability, especially with string bending or tremolo use. The nut slots need to be widened to snugly accommodate the 11-gauge strings, preventing slippage during vigorous playing.

Conversely, if nut slots are widened for heavier gauges and you later revert to lighter strings, filling and re-cutting the slots (as mentioned earlier) or replacing the nut entirely become options. Many players maintain a guitar neck with a nut slotted specifically for 12-gauge strings with a wound G, prioritizing stability and consistent performance.

Compensated Nuts: Fine-Tuning Intonation: Some companies have explored nut compensation to enhance intonation. Music Man Guitars, Earvana, and the Buzz Feiten tuning system are notable examples. Nut compensation, akin to saddle compensation at the bridge, involves minute adjustments to the string contact points on the nut. These subtle shifts improve intonation accuracy across the fretboard. On electric guitars, bridge saddles are intentionally set at varying distances for intonation purposes. Compensated nuts can be viewed as an extension of this principle. Do they make a difference? Yes, often subtly but measurably. Is the improvement universally noticeable? Not always. The traditional guitar, by its very nature, is an instrument with inherent intonation compromises. “Fan-fret” and “true temperament” fret designs address these complexities further, but those are topics for another discussion.

The compensated nut on a Music Man guitar

The compensated nut on a Music Man guitar

A compensated nut design on a Music Man electric guitar.

Nut Width and String Spacing Interplay: String spacing is directly related to nut width. A guitar’s nut width limits its string spacing, but there’s usually some flexibility to adjust string positions slightly inward or outward on the nut. If a low E string consistently slips off the fretboard edge, the nut slot might be cut slightly too far outwards and could be adjusted inwards. Remember, string spacing at the bridge is almost always wider than at the nut. Uniform string spacing from bridge to nut would feel awkward to play; strings need to converge towards the nut for optimal fretting comfort.

The Era of Slim Nut Widths: The late 1960s and early 1970s represent a distinct period in nut width history. Gibson produced guitars with exceptionally narrow nut widths of 1 and 9/16”. These “slim taper” necks are loved by some and disliked by others. They offer a very slender neck profile with closely spaced strings (due to the limited nut width). Players with slender fingers may find these widths comfortable, but those with average or larger hands often struggle with the cramped spacing. While similarly narrow nut widths existed on some other vintage guitars, they are largely uncommon today, except in vintage reissues.

Fingerboard Shrinkage and Nut Implications: Over decades, guitar fingerboards can shrink due to moisture loss and dehydration. Protruding fret ends are a telltale sign of fingerboard shrinkage. The wood shrinks, but the metal frets do not. Fingerboard shrinkage results in a slight reduction in nut width. Bound fingerboards can also shrink as plastics dry out. If a fingerboard has experienced significant shrinkage, a new nut cut to match the slightly reduced width and optimized string spacing may be beneficial.

Shrinkage happens to the best of us

Shrinkage happens to the best of us

Humorous image referencing fingerboard shrinkage.

Wrapping Up: The Nut’s Crucial Role

As is often the case, even a seemingly simple guitar component like the nut reveals surprising depth upon closer examination. Hopefully, this exploration has been informative, engaging, and not overly verbose. It is remarkable that such a seemingly small and frequently overlooked part can have such a significant impact on a guitar’s overall performance. Perhaps this level of detailed consideration of every guitar aspect is a testament to true guitar obsession!

This in-depth article was written by Mathew Jenkins, a self-confessed guitar nut.