The dream of crafting a personalized electric guitar has resonated with musicians and makers for decades. For me, that dream took a high-tech turn: 3D printing an electric guitar. The concept sparked a whirlwind of questions. Could a 3D printed body withstand string tension? Would it warp over time? Was specialized hardware essential? And the ultimate question for any guitar player: would a plastic body produce a truly awful tone compared to the rich resonance of traditional tonewoods? Surprisingly, online resources offered more questions than definitive answers.

Of course, I wasn’t venturing into uncharted territory. The internet is dotted with attempts at 3d Printed Guitars, some achieving impressive visual results. However, many of these projects fell short on playability. Others, while aesthetically pleasing, lacked accessible 3D models, clear instructions, or were burdened by complexity and exorbitant costs.

That’s when the gauntlet was thrown. I decided to design my own fully 3D printable electric guitar from the ground up. This wouldn’t just be another 3D printing experiment; it would be a quest to create a genuinely playable instrument using accessible technology.

Design Philosophy: Keeping the 3D Printing Community in Mind

My design process wasn’t just about personal ambition; it was driven by a desire to empower the 3D printing community. I wanted to create a project that others could easily replicate, learn from, and ultimately, rock out with. Before even sketching a single line, I established a core set of design priorities:

- Simplicity is Key: The design had to be straightforward, avoiding convoluted assemblies with countless parts. Forget complex reinforcement structures or obscure hardware. Easy assembly was paramount.

- Affordability Matters: Let’s be real, if I were prepared to spend a fortune, I’d be browsing Fender or Gibson showrooms. This project needed to be budget-friendly, leveraging the cost-effectiveness of 3D printing.

- Globally Accessible Hardware: Sourcing components should be hassle-free, with hardware readily available and offering worldwide shipping. No obscure, hard-to-find parts.

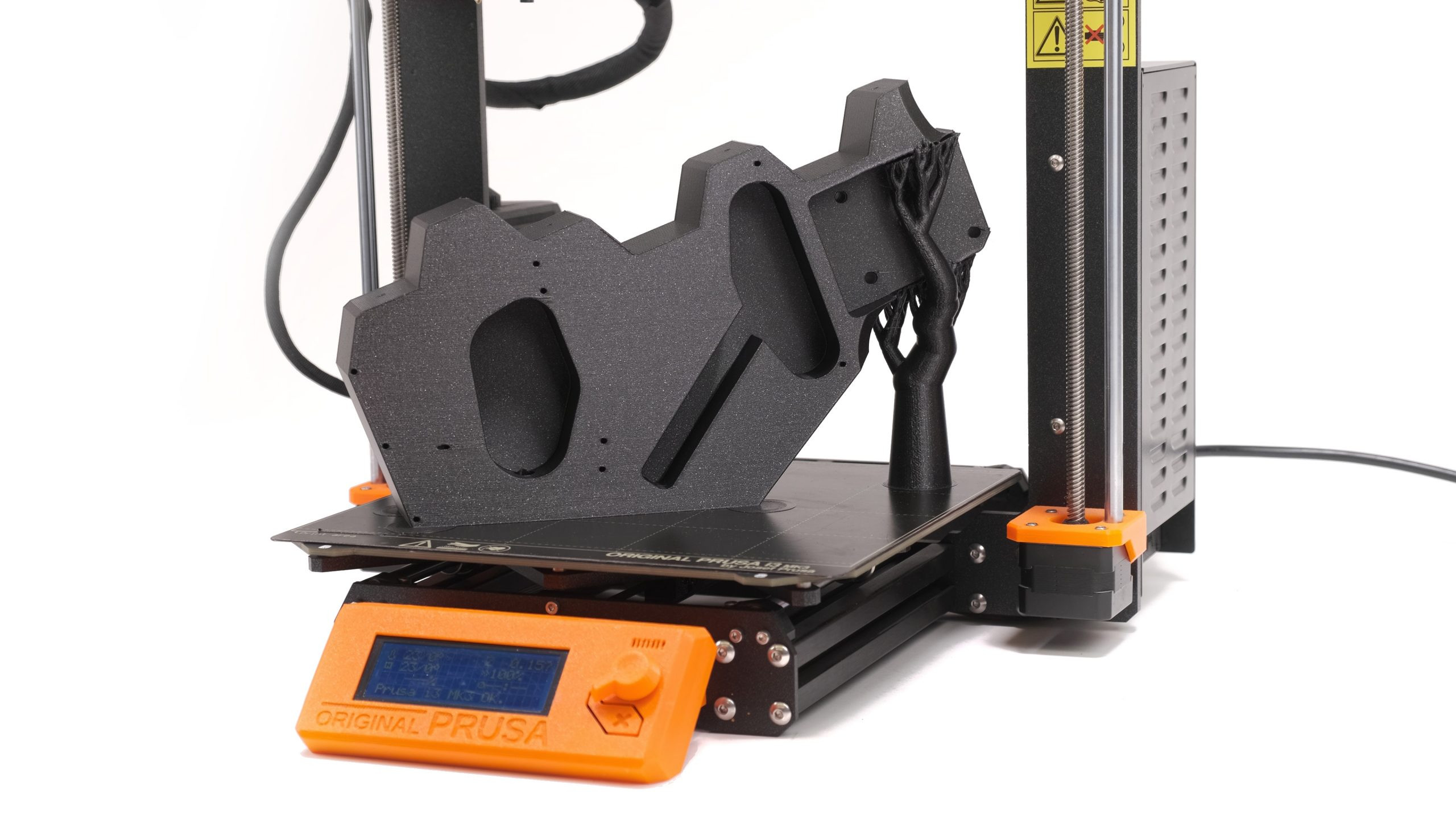

- Printable on a Prusa i3 MK3S+ (or Similar): This was a critical constraint. If the design couldn’t be realized on a printer with a build volume of 25×21×21 cm, it would exclude a significant portion of the maker community. This limitation was embraced as a design challenge.

- Playability is Non-Negotiable: This wasn’t about creating a plastic novelty. The final product had to be a legitimately playable guitar, in tune across its entire range. No plastic gimmickry allowed.

- Visually Striking Design: Beyond functionality, the guitar had to look amazing. 3D printing opens up design possibilities beyond traditional guitar shapes, and I wanted to fully exploit that potential.

Simplifying the Structure: Addressing String Tension and Hardware Choices

The most pressing concern from the outset was managing the immense force exerted by guitar strings on the body and neck. While exact figures vary, the consensus points to around 50 kg (110 lbs) of tension, depending on string gauge. This force constantly tries to bend the guitar in half, pull the bridge off the body, and warp the neck.

The neck solution was almost immediately obvious: utilize a real wooden neck. While purists might argue it compromises the “fully 3D printed” ideal, the neck is arguably the instrument’s most crucial component. Attempting to 3D print a neck introduces immense complexity and potential compromises in playability. Wooden necks offer unparalleled smoothness, straightness, durable metal frets, and an integrated truss rod for precise relief adjustments.

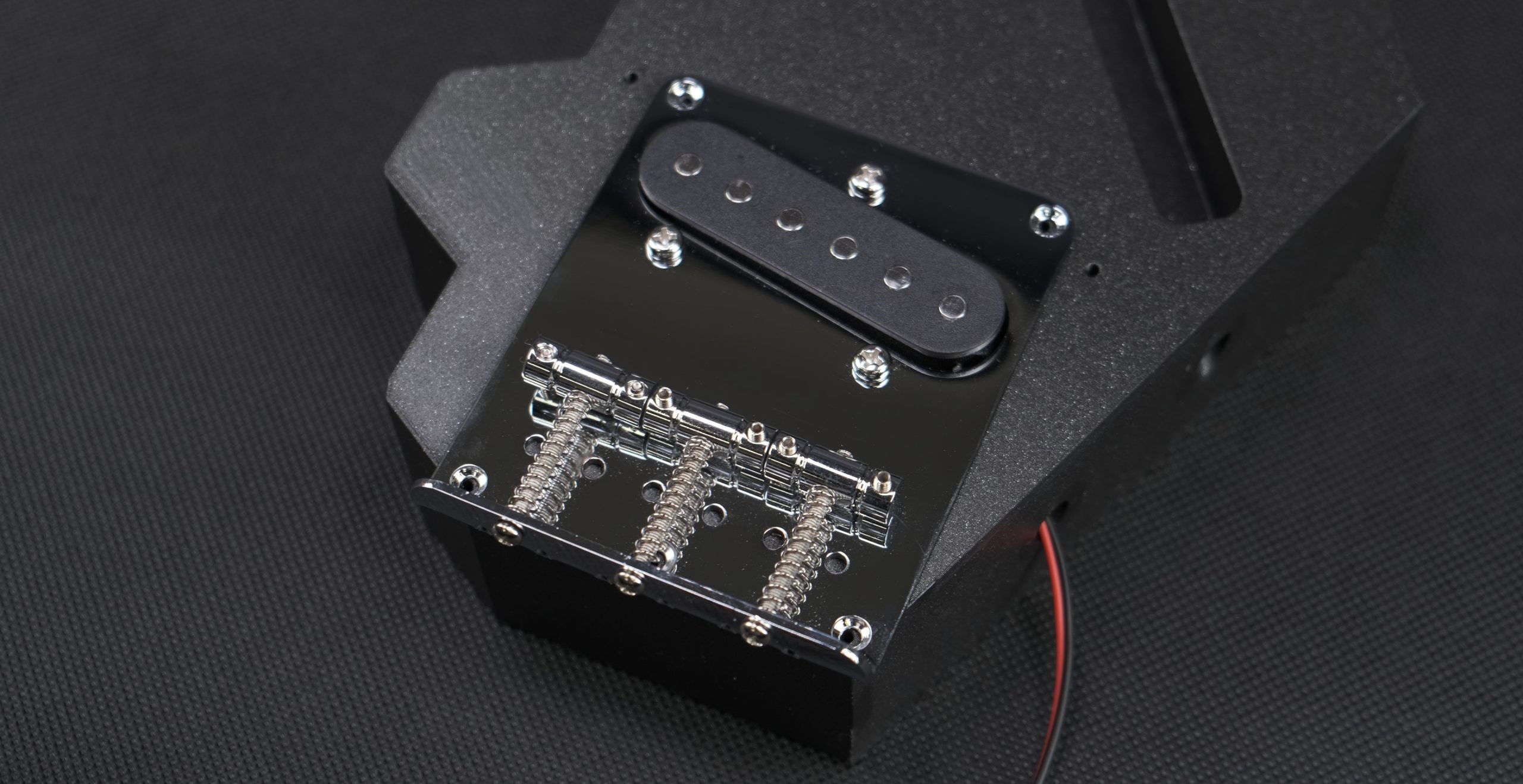

However, the bridge presented a more intricate puzzle. The bridge, a small metal piece anchoring the strings to the body, typically relies on a few screws for attachment. Examining common guitar designs, one bridge type stood out as exceptionally well-suited for a 3D printed guitar: the Telecaster bridge.

Unlike designs with diminutive bridges often secured by just two screws, the Telecaster bridge is a substantial metal plate. It not only anchors the strings but also integrates the bridge pickup and boasts up to five mounting holes with widely spaced screws. This design distributes string tension across a larger area of the printed body, significantly enhancing stability.

Image: Close-up of a Telecaster bridge, highlighting its large metal plate and multiple mounting screws, chosen for its suitability for a 3D printed guitar body due to superior force distribution.

Furthermore, the Telecaster’s single additional neck pickup simplifies wiring and design. Finally, the volume and tone knobs, along with the pickup selector switch, are conveniently mounted on a separate metal control plate, secured to the body with just two screws. This further streamlines the project by avoiding individual integration of multiple controls.

This project builds upon previous explorations into 3D printing guitar accessories. Earlier, we explored the surprising effectiveness of 3D printed guitar picks and the versatility of 3D printed guitar accessories like capos and strap locks. These earlier experiments paved the way for this more ambitious project.

Image: A selection of 3D printed guitar accessories, including picks and a capo, showcasing the potential of 3D printing for guitar components and accessories.

Sourcing the Hardware: The Harley Benton Kit Revelation

With the Telecaster hardware path chosen, the next step was sourcing the necessary components. Generally, there are three primary approaches:

- Guitar Scavenging: Disassemble a budget Telecaster guitar for its parts.

- Component-by-Component Purchase: Acquire each part individually.

- Hardware Kit Solution: Purchase a dedicated Telecaster hardware kit.

Dismantling a functional guitar felt wasteful unless a severely damaged instrument with salvageable hardware and neck could be found.

Purchasing components individually is feasible but quickly escalates in cost. The essential parts include:

- Guitar neck with tuning pegs

- Standalone single-coil pickup (neck pickup)

- Bridge with integrated single-coil pickup (bridge pickup)

- Telecaster control plate assembly (3-way switch, volume and tone knobs)

- Output jack

The stark reality is that buying individual components is expensive. Even opting for the most budget-friendly options can easily accumulate to several hundred dollars.

This is where the project took an unexpected turn towards affordability: the Harley Benton Electric Guitar Kit T-Style! Priced at an astonishingly low $79, this kit includes all the necessary hardware, pre-wired with simple snap-together connectors. Offered by Musikhaus Thomann, a major global music instrument retailer based in Germany, it also fulfilled the requirement of worldwide shipping.

The kit’s incredible price and convenience were irresistible. The project transformed into a “order this kit and print the body” endeavor. The Harley Benton kit includes a basic, unpainted wooden body. While functional, its rudimentary nature made it an easy decision to replace it with a custom 3D printed body.

Designing the Prusacaster Body: Fusion 360 and Creative Freedom

Fusion 360 became my digital workshop for designing the guitar body. Accurate placement of screw holes, neck mounting points, and electronics cavities was paramount.

The Harley Benton kit’s included wooden body proved invaluable as a dimensional reference. By photographing the body alongside a ruler from a distance (minimizing perspective distortion) and utilizing Fusion 360’s “Calibrate” tool, I created a scaled template. Calibrating against the entire 50cm length of the ruler minimized scaling errors.

I then meticulously traced the positions of all holes in a 2D sketch within Fusion 360. Digital calipers verified feature distances against the sketch, accounting for minor perspective distortion, especially for widely spaced holes. Bridge placement accuracy was paramount, ensuring proper alignment with the neck for centered strings and correct intonation. The 12th fret needed to be precisely midway along the string length for accurate tuning, a principle known as guitar intonation. While the Telecaster bridge offers intonation adjustment range, precise initial placement is crucial.

Image: Measuring the wooden body from the Harley Benton kit with digital calipers, used to create an accurate digital template in Fusion 360 for designing the 3D printed guitar body.

With mounting points accurately defined, creative freedom took over. While utilizing Telecaster hardware, a simple Telecaster body replica felt like a missed opportunity. 3D printing liberates design from traditional manufacturing constraints, demanding exploration of new forms.

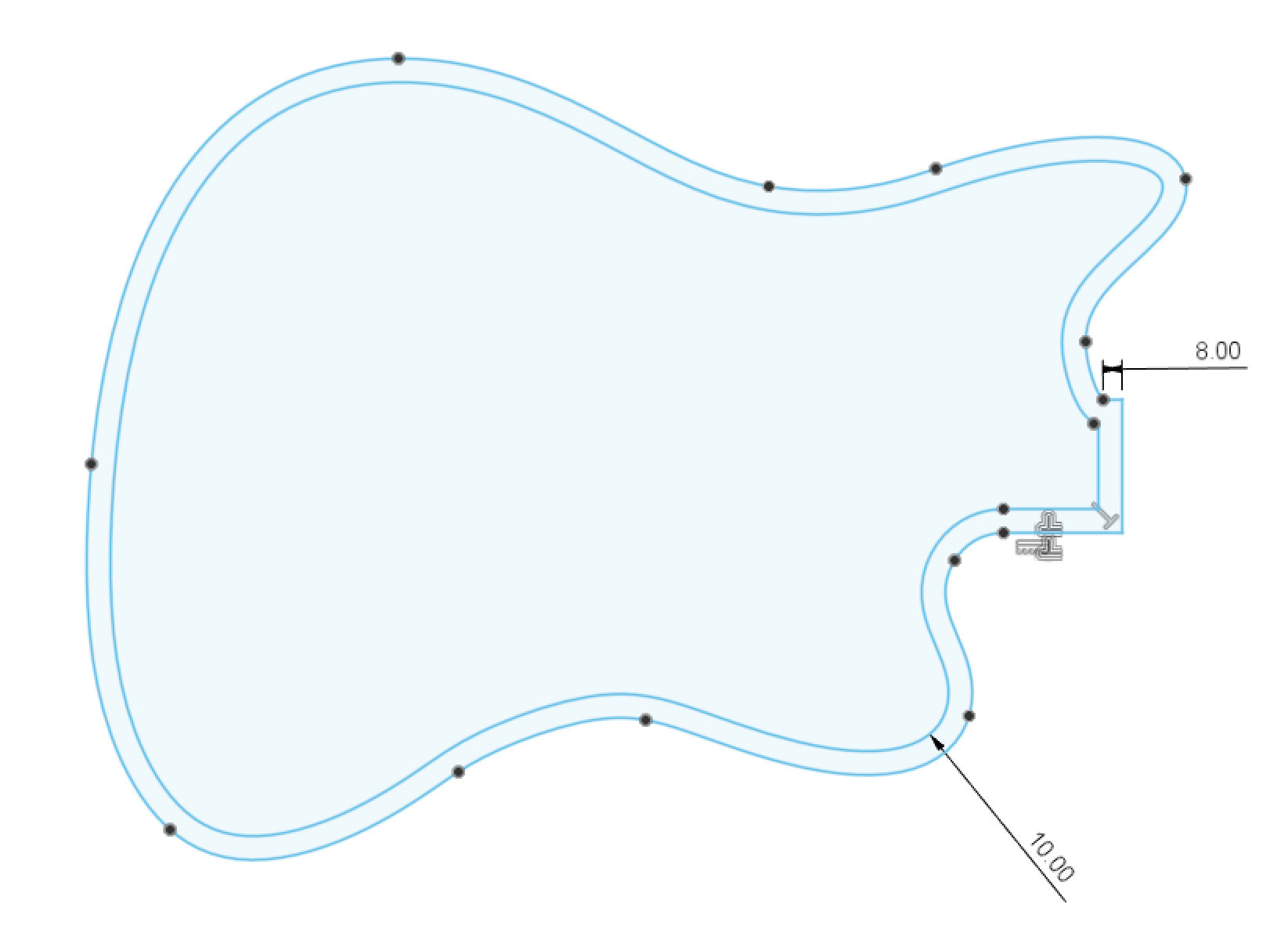

Shapes inspired by Fender Jazzmaster and Mustang guitars resonated with my aesthetic preferences. Fusion 360’s Spline tool allowed me to sculpt a body shape evoking these influences.

Image: A 2D spline sketch in Fusion 360, outlining the basic shape of the Prusacaster guitar body, inspired by Fender Jazzmaster and Mustang designs.

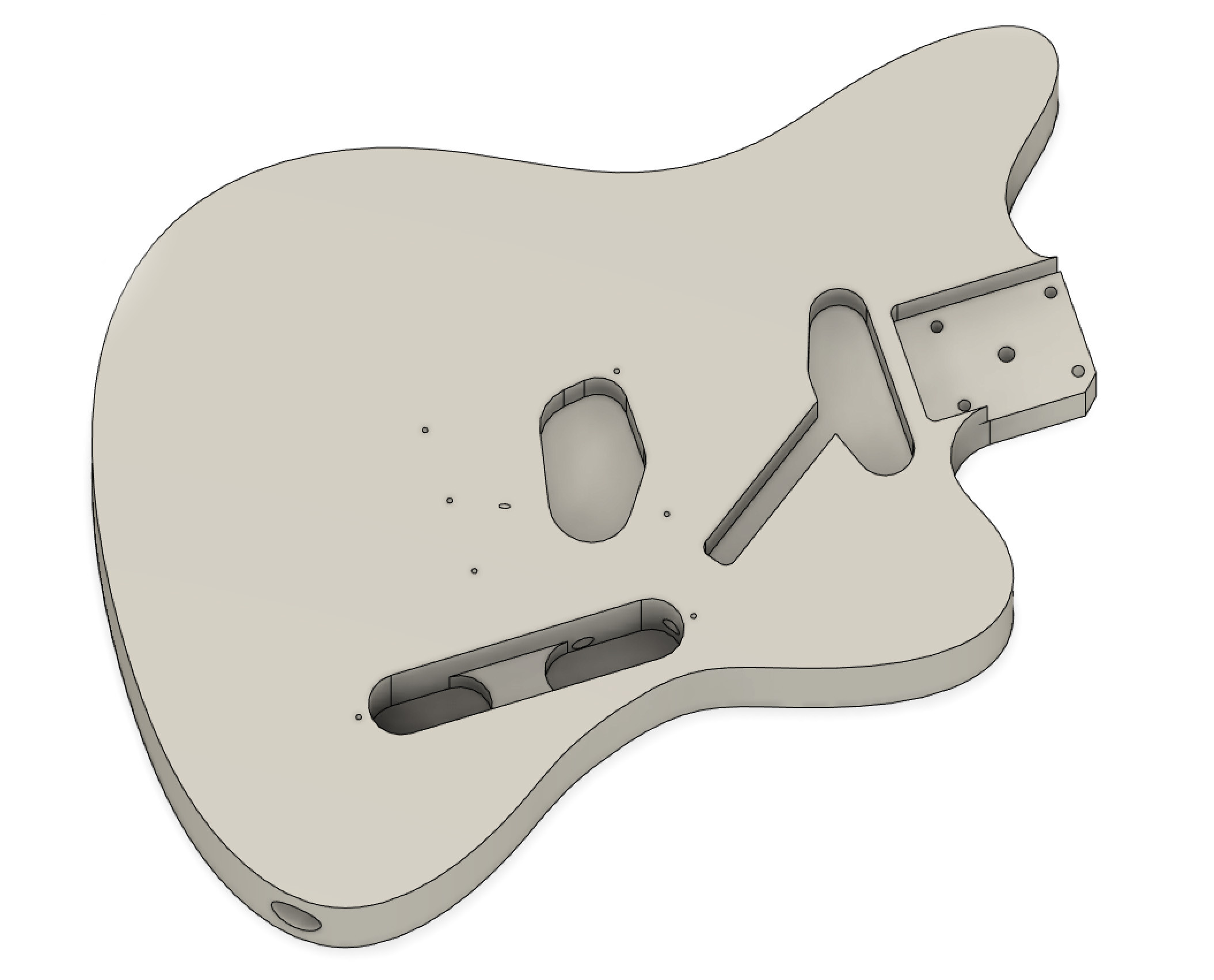

The standard guitar body thickness of 45mm was used for extrusion, creating the initial 3D form. Hole and cavity extrusions for electronics followed, using the previously created template. “Tunnels” connecting cavities ensured wiring accessibility. Pickguard and bridge coverage meant pickup cavities could be slightly oversized. A larger hole on the lower edge provided access to the control plate cavity for the output jack. The basic guitar model was now complete.

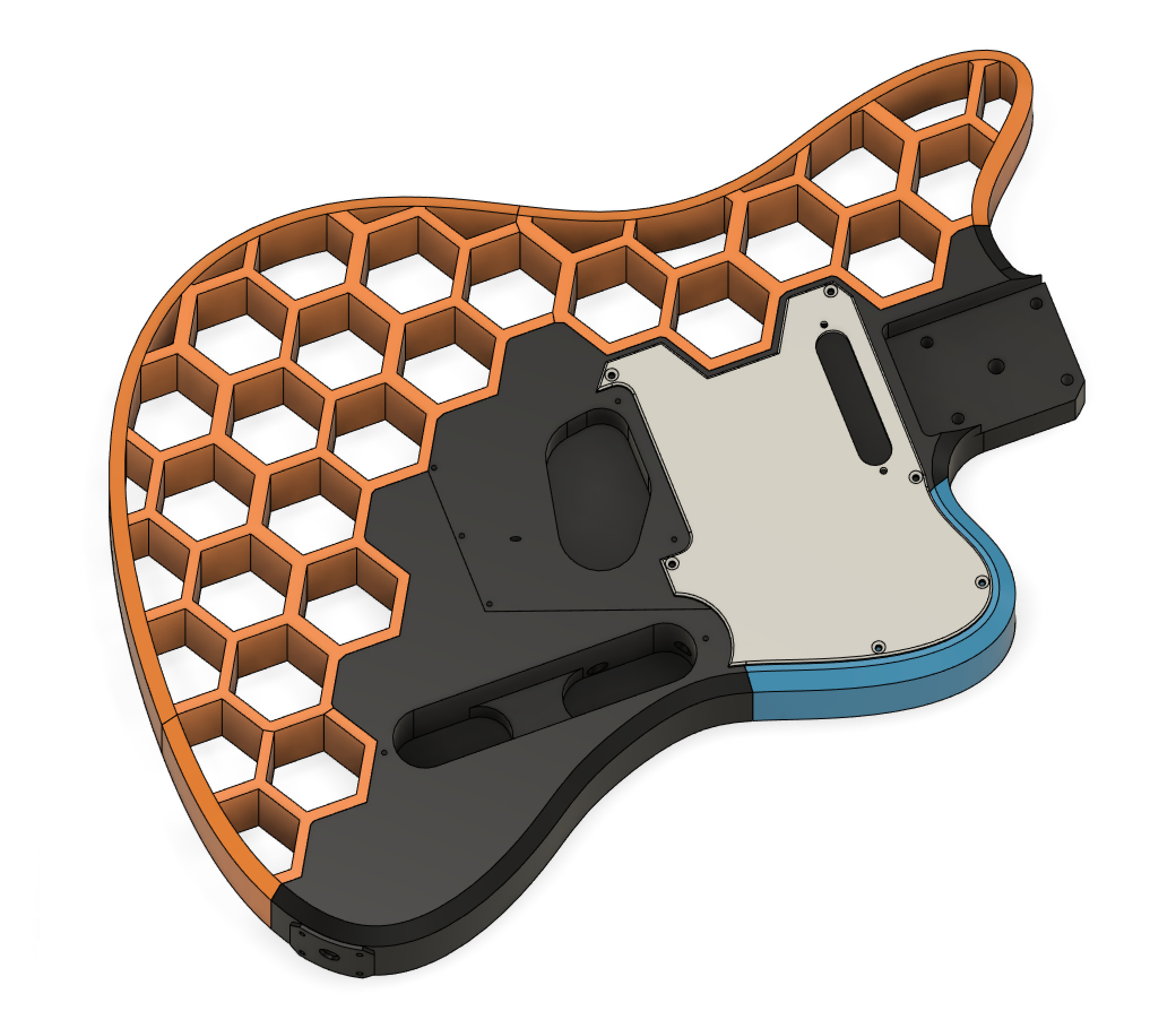

Image: The extruded 3D model of the Prusacaster guitar body in Fusion 360, showing the basic form with initial cavities and holes for hardware and electronics.

However, the model’s size exceeded the build volume of most desktop 3D printers, including the Original Prusa XL. Segmentation into printable pieces was necessary.

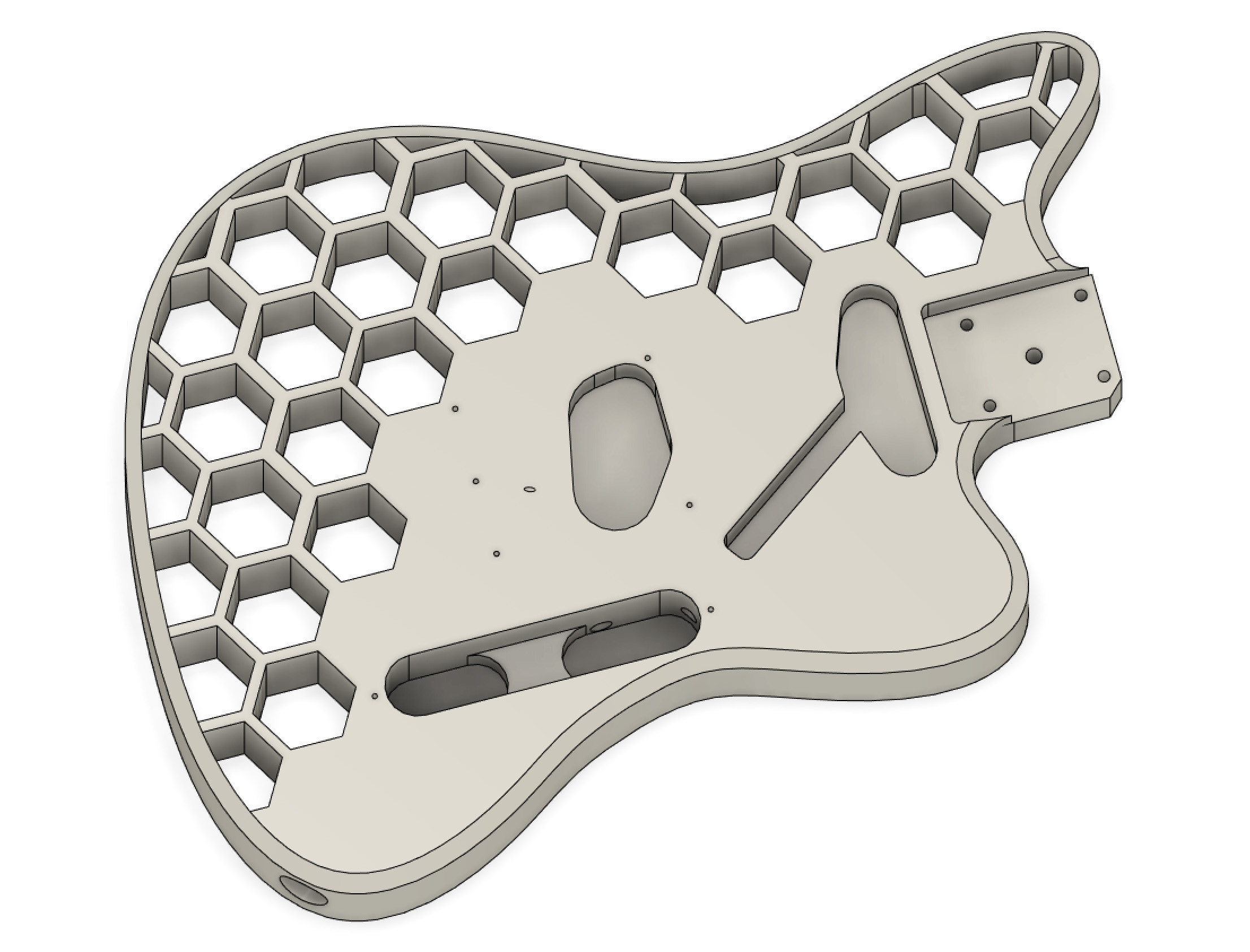

Beyond size constraints, the design lacked visual flair. 3D printing’s design freedom prompted experimentation with cutouts. Hexagons emerged as the design motif. Beyond aesthetics, hexagons offered functional advantages. Their edges provided natural split lines for segmenting the model, creating seams that appeared intentionally designed. A prominent chamfer along the top edge enhanced playing comfort and armrest ergonomics.

Image: The Prusacaster guitar body design incorporating hexagon cutouts and a chamfered top edge, adding visual interest and functional segmentation points for 3D printing.

Segmenting for Printing: Puzzle Pieces of a 3D Printed Guitar

Recalling the 50 kg string tension, a crucial segmentation principle emerged: the guitar section between the neck and bridge should be a single, continuous piece. Strengthening joints in this critical load-bearing area would introduce unnecessary complexity.

Fortunately, with some spatial ingenuity, this was achievable. The hexagon pattern defined the top edge’s cut line. Another logical cut was placed just below the bridge mounting holes, minimizing the central piece’s length. A clever angled cut on the lower left allowed for diagonal print bed orientation, maximizing printable size within the MK3’s volume. This critical central piece could even be printed without supports, although organic supports in PrusaSlicer were chosen for superior overhang surface finish.

Image: A screenshot from PrusaSlicer showing the central piece of the Prusacaster guitar body oriented diagonally on the print bed of an Original Prusa i3 MK3, demonstrating printability within the printer’s volume.

The remaining segmentation was straightforward. The lower body section, lacking hexagons, was split into two pieces to fit the 25×21 cm print area. The top section was divided into three pieces for the same reason.

The pickguard, serving as a mounting point for the neck pickup, was the final major piece. Its shape was naturally defined by the surrounding body edges, inset by 3mm.

Segmenting the body offered an unexpected aesthetic advantage: multi-color printing. The Prusa Research color palette – black and orange – was an obvious choice. Complementary teal/blue accents, particularly on the small lower-right piece, added vibrant detail.

Image: A rendered image of the final Prusacaster 3D printed guitar design, showcasing the segmented body with hexagon detailing and multi-color printing in black, orange, and teal.

With the Prusacaster model finalized, it was time to move from the digital realm to physical creation.

Printing and Assembly: From Digital Design to Tangible Instrument

Material Selection for the Core: PLA’s Stiffness Advantage

The central body piece, bearing the brunt of string tension, demanded careful material selection. While PETG might seem like an intuitive choice for “strength,” stiffness (bending modulus) was the key requirement. Surprisingly, good old PLA excelled in this area. PLA also aligned with the project’s simplicity and affordability goals.

PLA’s primary drawback is its lower temperature resistance. While the substantial central piece can withstand direct sunlight for reasonable durations, leaving the guitar in a hot case on a summer day could pose a risk. For enhanced temperature resistance, materials like Prusament PC Blend Carbon Fiber or Prusament PA11 Carbon Fiber are suitable alternatives, albeit more expensive and requiring more demanding print settings. Given Prague’s temperate climate, PLA was deemed sufficient for this build. After a year, the PLA centerpiece remained structurally sound.

To validate fitment, a test print of the central piece using default PrusaSlicer settings was conducted. Successful fitment led to attaching the neck, bridge, and strings to this minimalist guitar frame. Remarkably, even in this skeletal form, the guitar was functional and playable, albeit lacking electronics and visual completeness.

Image: The minimalist Prusacaster guitar with only the central 3D printed piece, guitar neck, bridge, and strings attached, demonstrating basic functionality and playability even in an incomplete state.

Addressing Material Creep: Increasing Perimeter Count

Material creep, the slow deformation of solid materials under sustained stress, was another concern. Initial tests confirmed this phenomenon. After a month under string tension, the PLA centerpiece exhibited slight bending. This wasn’t unexpected, as the default PrusaSlicer profile’s 2 perimeters, suitable for general prints, proved insufficient for this load. Reprinting the piece with 7 perimeters and 25% cubic infill completely resolved the creep issue, providing the necessary structural rigidity.

String Gauge Selection: Minimizing Tension

Guitar strings come in varying gauges (thicknesses). Lighter gauge strings offer easier playability and note bending but are more prone to breakage and produce slightly less volume. Heavier strings deliver increased volume and sustain but demand more finger pressure and, crucially, exert greater tension on the guitar neck. Opting for lighter gauge strings, such as 9 gauge, reduces stress on the 3D printed centerpiece.

Printing the Remaining Components: Material Flexibility

The remaining body pieces experience minimal stress, primarily needing to support the guitar’s weight on a strap and withstand cable connections. Material choice for these parts becomes less critical. Prusament PETG Prusa Orange was used for the top hexagon sections, Prusament PLA Galaxy Black for the lower switch-housing piece, and Prusament PLA Azure Blue for the small accent piece. Default PrusaSlicer profiles were used for all these parts.

Image: All the 3D printed parts of the Prusacaster guitar body in various colors (orange, black, and blue) laid out before assembly, showcasing the multi-part construction and color scheme.

Assembly: Bonding the Pieces

The segmented body pieces feature large contact surfaces for robust adhesion to the central piece. Generous application of superglue securely bonds the sections. M3 screw holes in the hexagon pieces offer optional mechanical reinforcement, particularly for strap button mounting points, although screw access is somewhat challenging and their use is considered optional for general assembly.

Wiring and Grounding: Electrifying the Prusacaster

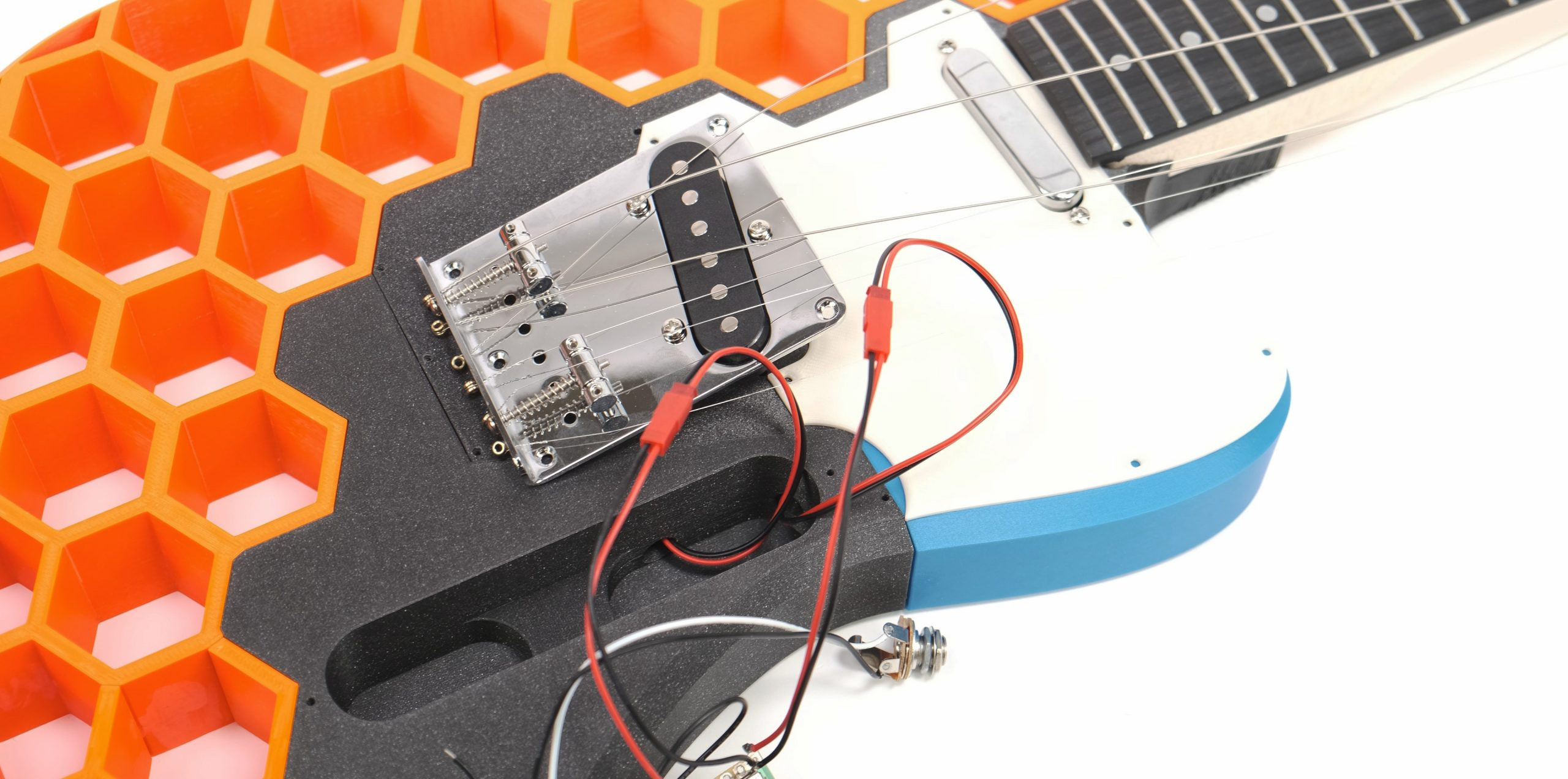

The Harley Benton T-style kit’s pre-wired electronics, utilizing JST connectors, simplified wiring significantly. Connecting the top pickup cables to the corresponding selector switch cables is crucial for correct switch operation.

Image: Close-up of the pre-wired electronics and JST connectors from the Harley Benton guitar kit, highlighting the simplified wiring process for the 3D printed guitar project.

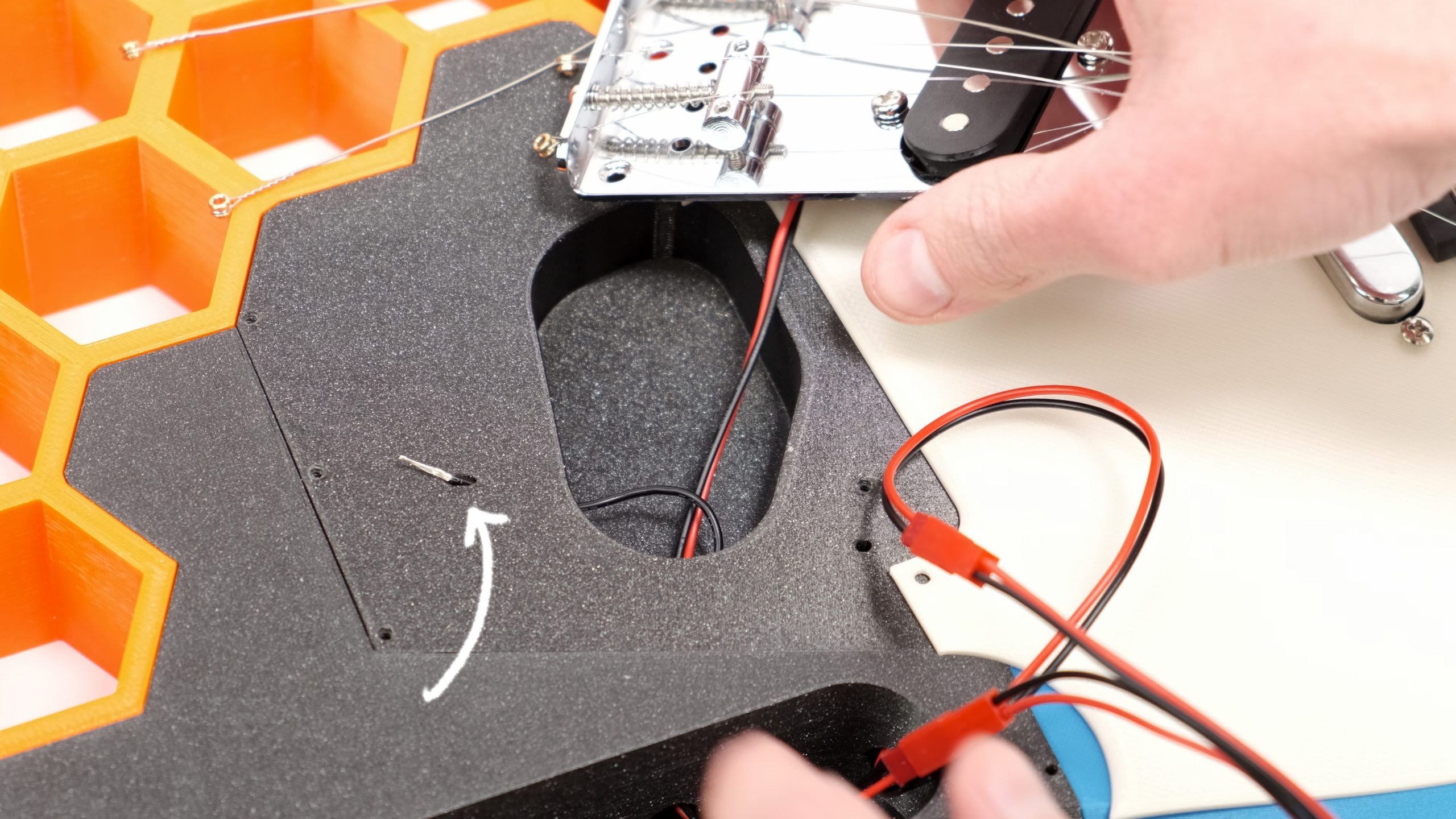

A seemingly unconnected black wire in the wiring harness serves a vital function: string grounding. A channel in the central printed piece, running under the bridge, accommodates this wire. Stripping insulation from the wire, slightly loosening the bridge, routing the wire through the channel, and retightening the bridge crimps the wire, establishing grounding. This grounding significantly mitigates unwanted buzzing, a common issue even in higher-end guitars, and especially relevant when using budget components.

Image: Diagram highlighting the grounding wire being routed through a channel under the bridge of the 3D printed guitar body, demonstrating the string grounding technique to reduce electrical noise.

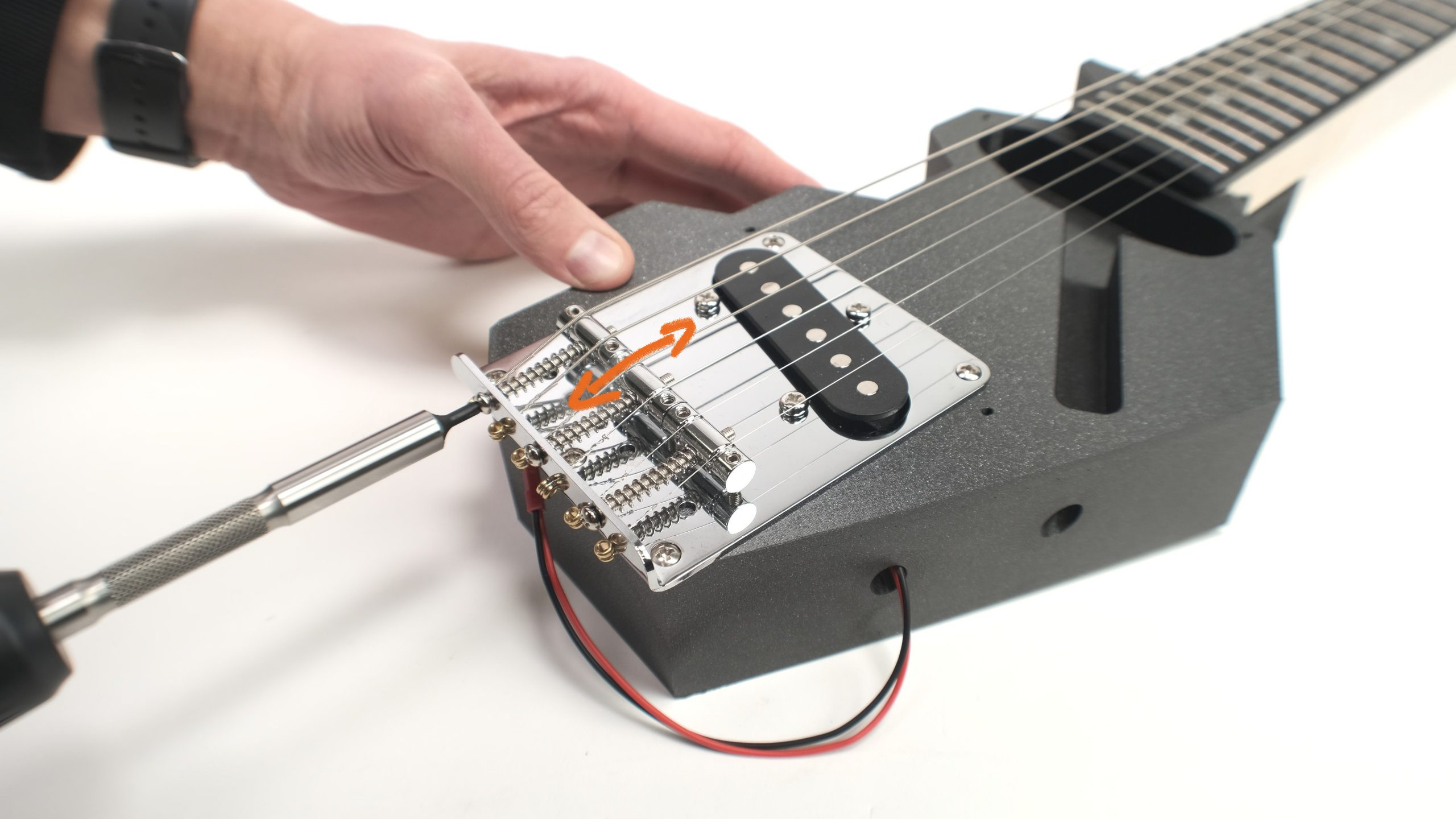

Final Touches: Intonation Adjustment for Perfect Tuning

With the guitar fully assembled and strung, tuning and intonation adjustment are the final steps. Guitar intonation ensures accurate tuning across the entire fretboard. After tuning the strings, compare the open string note to the note at the 12th fret. Significant pitch discrepancies indicate intonation adjustments are needed. The Telecaster bridge simplifies this process. Adjust the bridge saddle (the string’s resting point) by turning its adjustment screw. If the 12th fret note is flat (lower pitch), move the saddle towards the neck. If sharp (higher pitch), slightly loosen the string first and then move the saddle towards the bridge. Telecaster saddles often serve two strings, requiring a balanced adjustment for both.

Image: Close-up of intonation adjustment being performed on the Telecaster bridge of the 3D printed guitar, showing the saddle adjustment screws used to fine-tune string length and intonation.

The Completed Prusacaster: A 3D Printed Guitar Success

Image: Three images showcasing the fully assembled Prusacaster 3D printed guitar from different angles, highlighting its unique design, multi-color body, and overall aesthetic.

Playability and Verdict: Beyond Expectations

The Prusacaster’s playability is genuinely surprising. Blindfolded, one might not discern it from a traditionally manufactured guitar. Tuning stability and intonation are remarkably accurate. While not expected to surpass high-end Telecasters due to budget components, its performance for the cost is exceptional.

Build Your Own Prusacaster: Download and Create!

Overall, the Prusacaster project exceeded expectations. For those eager to embark on their own 3D printed guitar journey, the 3D model is available for free download on Printables.com: Download the 3D model from Printables.com. The download includes STEP files for all parts and a single-piece basic guitar design, along with a DXF drawing of hole positions.

Download the model from Printables.com

This project is a testament to the accessibility and creative potential of 3D printing. Download the model, unleash your creativity, and build your own Prusacaster! Enjoy the rewarding experience of crafting a unique, playable instrument.